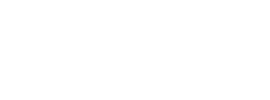

4.1 Maintenance activities

While preventative maintenance was performed frequently, reactive maintenance and investigating comfort complaints make up a substantial proportion of facilities managers’ and contractors’ workloads.

4.2 Reasons for callout

The prevalence of reactive maintenance in the workload of the sector points to equipment most frequently being run to the point of complete breakdown and failure. HVAC systems are largely ‘out-of-sight, out-of-mind’ until they fail.

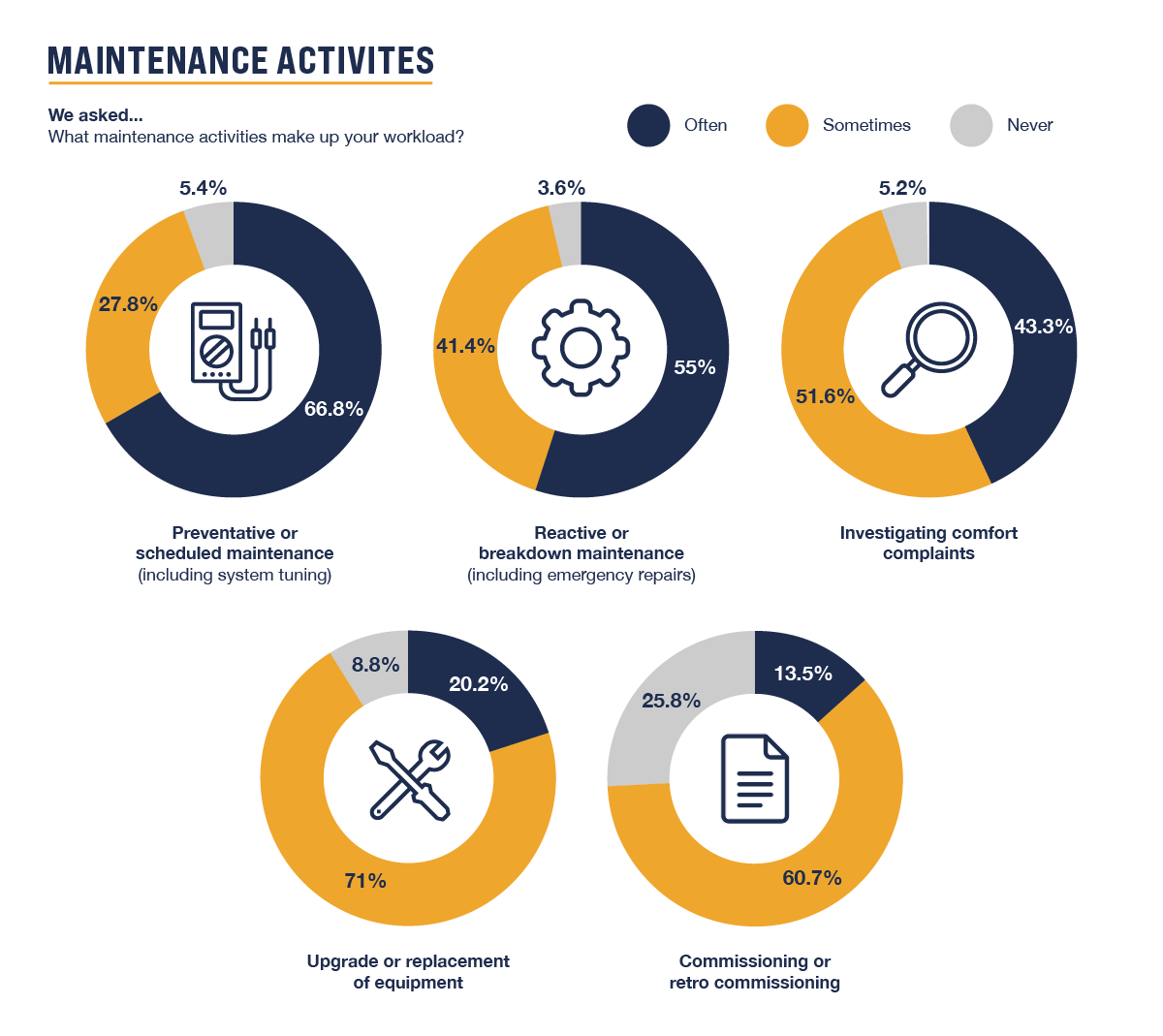

4.3 Fault types

The most common fault types encountered in mid-tier HVAC maintenance are simple fixes: clogged or dirty filters and thermostat failure or issues. These are largely avoidable through preventative maintenance.

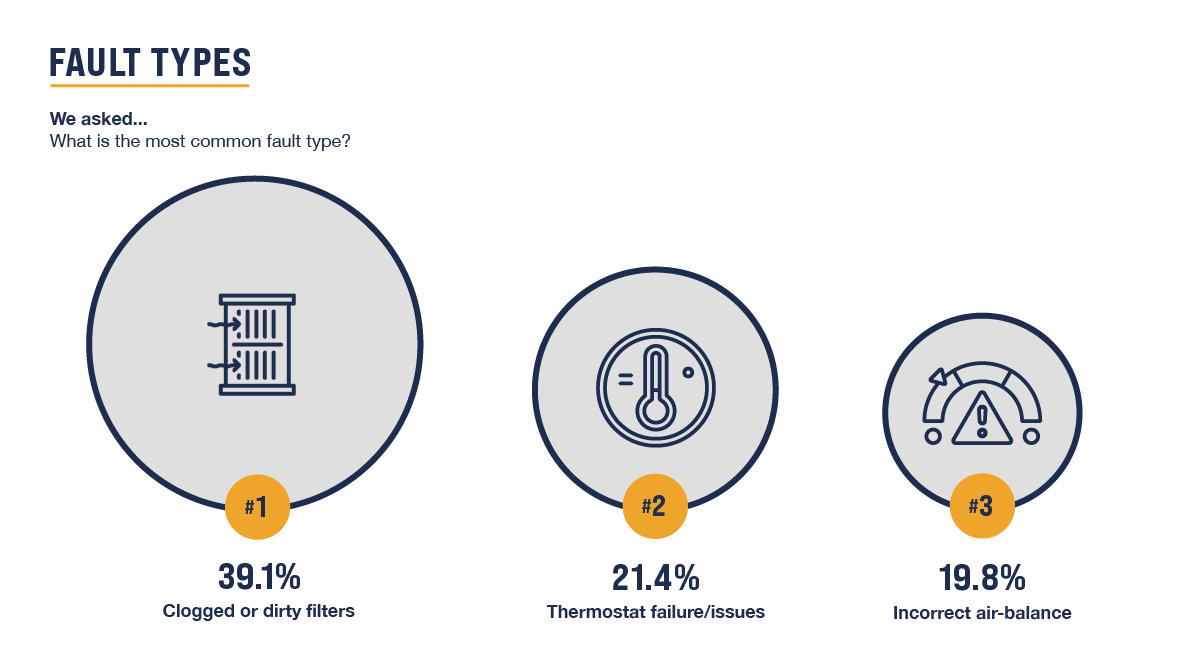

4.4 Replacing equipment

Cost is by far the greatest consideration when making decisions to repair or replace system components. This outweighed the second-ranked most important factor, like-for-like replacement more than threefold.

4.5 Documentation systems

Documentation systems are key to the development of more proactive maintenance regimes. Poor record keeping makes it difficult to understand what maintenance has previously been done, which assets require maintenance and when. Documentation systems are rarely in place in mid-tier office buildings.